Enhancing Your Laser System with a High-Performance Galvo Motor

Enhancing Your Laser System with a High-Performance Galvo Motor

Blog Article

A Comprehensive Guide to Galvo Motors and Their Effect On Laser Systems

Galvo electric motors have actually arised as a critical part in the advancement of laser systems, supplying improved precision and efficiency throughout numerous applications. These gadgets assist in rapid positioning of optical elements, which is essential for jobs varying from detailed inscription to intricate clinical treatments (Galvo). As technology breakthroughs, the assimilation of closed-loop control systems and expert system assures to press the boundaries of what these electric motors can accomplish. The effects of these developments expand beyond plain performance renovations, increasing questions regarding future applications and industry improvements. What might this mean for the landscape of laser modern technology?

What Are Galvo Motors?

Galvo motors, brief for galvanometer motors, are precision tools used to manage the placement of mirrors or lenses in laser systems. These motors are important to numerous applications, including laser engraving, reducing, and estimate systems, where accurate positioning is critical for optimal performance. Galvo electric motors make use of a lightweight style that makes it possible for rapid movement, permitting high-speed procedure and accurate control of laser light beams.

Furthermore, galvo electric motors can be integrated with sophisticated control systems, permitting innovative programming and automation. This flexibility not only improves operational effectiveness yet likewise makes certain consistency in result. As a result, galvo electric motors have actually ended up being an essential component in contemporary laser technology, assisting in advancements in different areas by enabling exact adjustment of light with unprecedented rate and precision.

Just How Galvo Motors Operate

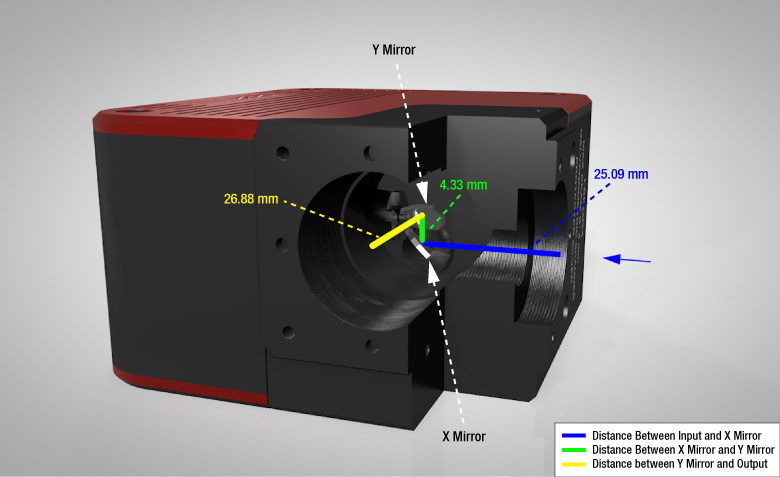

The operation of galvo motors depends on exact electro-magnetic mechanisms that help with precise and fast positioning of mirrors or lenses. At the core of a galvo electric motor system are rotating coils placed on a shaft, which connect with magnetic areas generated by long-term magnets. When an electric current is related to the coils, it develops an electro-magnetic pressure that creates the shaft to revolve. This turning is typically really quickly, permitting real-time changes to the angle of the mirrors or lenses.

Galvo electric motors are identified by their closed-loop control systems, which make use of comments from setting sensors to ensure accuracy. These sensing units keep track of the angular position of the mirrors, relaying information to the controller that changes the existing supplied to the motor. This responses loop permits fine-tuning of the motor's position, causing high repeatability and accuracy.

Additionally, the light-weight building of galvo motors reduces inertia, making it possible for quick action times vital for laser scanning applications. On the whole, the mix of electro-magnetic concepts and closed-loop comments systems allows galvo motors to execute complex tasks with outstanding accuracy and rate, making them crucial in sophisticated laser modern technologies.

Benefits of Galvo Motors

One of the crucial benefits of utilizing galvo motors in laser systems is their capability to achieve quick and precise positioning, which is critical for applications such as laser engraving, reducing, and scanning. This precision is mainly due to the high-speed action of galvo electric motors, enabling them to quickly adjust the angle of the laser beam of light with marginal delay.

An additional considerable benefit is their minimized inertia compared to typical stepper motors, which enables quicker velocity and deceleration. This particular not Homepage only boosts the general rate of laser procedures but additionally adds to the top quality of the completed item by decreasing motion blur.

Applications in Laser Solutions

Applications of galvo electric motors in laser systems cover a wide variety of sectors, showcasing their adaptability and effectiveness. Mostly utilized in laser etching and noting, galvo motors allow precise control over the laser beam of light's position, assisting in intricate styles on numerous materials such as metals, plastics, and glass. Their quick response times and accuracy significantly improve manufacturing performance, making them vital in manufacturing processes.

In the realm of laser cutting, galvo electric motors permit high-speed operations, minimizing the moment required for elaborate cuts while preserving side top quality. This capability is especially helpful in fields like automobile and aerospace, where precision is essential. Galvo motors are important in laser scanning applications, such as in 3D laser scanning and imaging systems, where they assist in fast information procurement and evaluation.

Clinical applications additionally take advantage of galvo modern technology, specifically in laser surgery and diagnostic equipment, where accurate beam of light control is critical for efficient end results. In enhancement, the emergence of laser-based micro-machining procedures has actually seen the fostering of galvo electric motors, improving the capability to do fragile operations with exceptional accuracy. In general, galvo motors play an essential role beforehand laser technology throughout varied fields.

Future Fads in Galvo Technology

Increasingly, advancements in galvo weblink modern technology are positioned to reinvent different sectors that depend on laser systems. One substantial pattern is the combination of expert system (AI) and maker discovering algorithms right into galvo control systems. These innovations enhance accuracy and versatility, permitting real-time changes based upon dynamic ecological conditions or product buildings.

An additional emerging pattern is the development of higher-speed galvo electric motors, which assist in faster processing times in applications such as laser inscription and cutting - Galvo Scanner. As industries require quicker turnaround times, these advancements will come to be vital for keeping competitive benefit

Furthermore, miniaturization of galvo parts is making laser systems much more functional and small. This fad is particularly pertinent in sectors such as clinical tools, where area restraints are vital.

Conclusion

Galvo electric motors have arised as an essential part in the development of laser systems, providing boosted precision and performance across numerous applications.Galvo motors, brief for galvanometer motors, are precision tools utilized to regulate the setting of mirrors or lenses in laser systems. Largely used in laser noting and engraving, galvo motors allow exact control over the laser beam's setting, facilitating elaborate layouts on various products such as steels, plastics, and glass. Galvo motors are critical in laser scanning applications, such as in 3D laser scanning and imaging systems, where they facilitate rapid information procurement and analysis.

As improvements in closed-loop control systems and fabricated intelligence combination find more info proceed to evolve, the capacity for galvo electric motors to better transform laser systems stays considerable, encouraging increased speed and minimized movement blur, thereby expanding their utility across varied commercial fields.

Report this page